evaluated the interface mechanism of multi-material for high compatibility materials, PLA-PLA, and low compatibility materials, PLA-TPU, for tensile strength. This feature is given by the shape of the mating bodies.

That material can be deposited side by side, on top of each other (layered), or a combination of both. Another benefit was the possibility of printing multi-color and multi-material components with the cost of an extra quantity of material consumed on transition or purge towers.Ī multi-material component requires a three-dimensional object for each material and is imperatively necessary to use chemically compatible materials (e.g., ABS-PC) with similar melting ranges. Īlong with the development of multi-extrusion systems and multi-feeding mechanisms, new possibilities appeared regarding quality, complexity, and build orientation of parts due to the soluble materials or the possibility of using incompatible materials for support structures. Due to the wide range of available thermoplastics, from standard polymers (e.g., polylactic acid-PLA) to engineering-grade (e.g., acryl butadiene styrene-ABS, polycarbonate-PC) and high-performance ones and due to the good dimensional accuracy, FFF is one of the most used AM technologies for plastic processing. In order to provide the desired physical properties, multiple parameters must be adjusted depending on the product's functional requirements and the used material (e.g., extrusion width, number of perimeters, extrusion temperature, deposition speed.

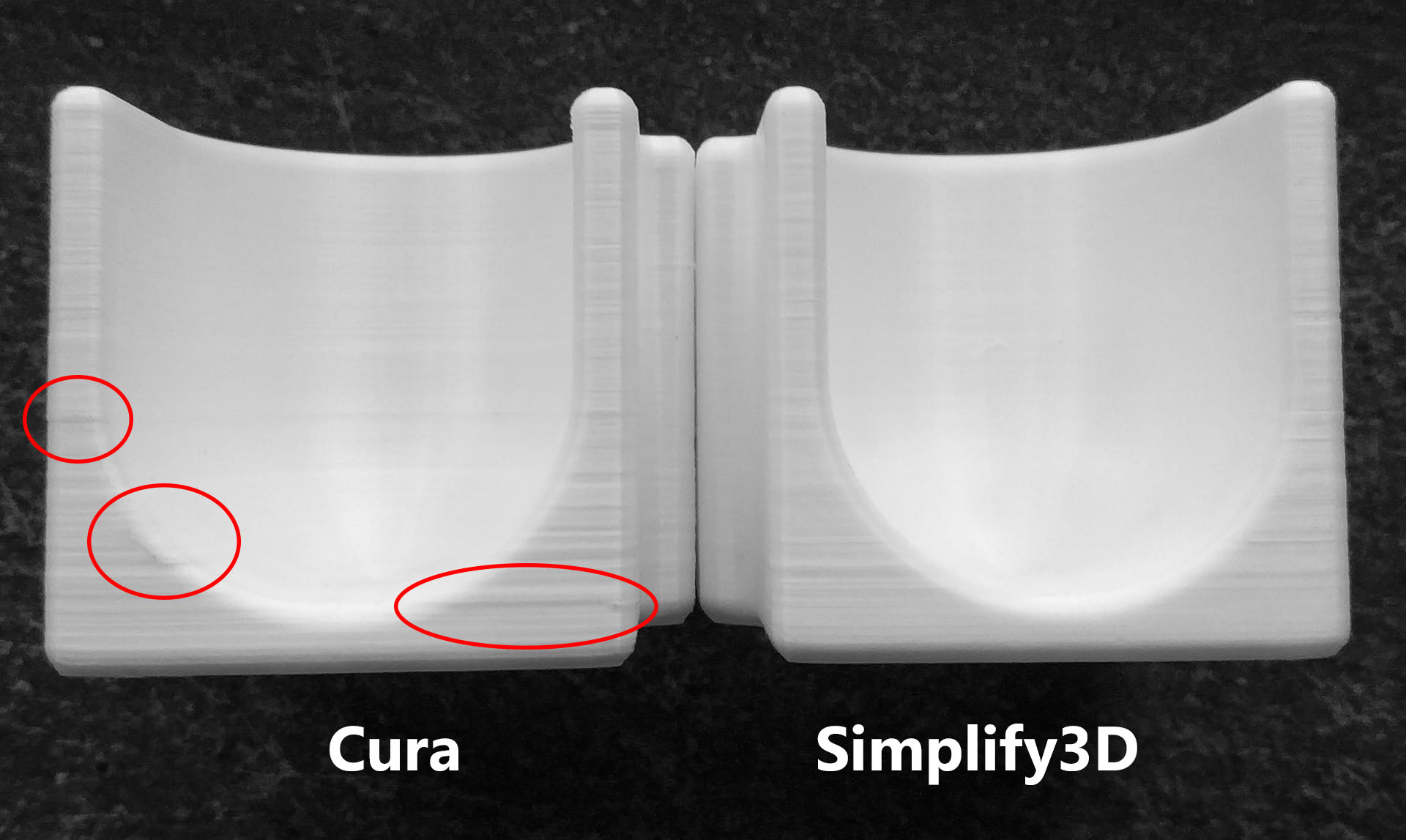

#Cura vs ultimaker cura software

All AM processes use three-dimensional input data in mesh format (e.g., STL), transferred in the machine's software and then sliced in layers with a defined height. The results show that the mechanical properties of multi-material bonds can be enhanced conveniently by adding an overlap degree between mating bodies.įused filament fabrication (FFF) is an additive manufacturing (AM) technology in which a thermoplastic material is forced through a heated nozzle and precisely deposited in the desired regions in the shape of layers built on top of each other. Furthermore, for a broader understanding of the bond formation, the design of the experiment comprises two groups referring to the material blend along with their melting ranges and join geometry, which is constrained with regard to nozzle output size.

For this reason, this paper aims to investigate if the mechanical properties of compatible polymers can be enhanced by modifying the regular flat to a flat surface with different shape interfaces and an overlap degree between them. However, regular bond formation of part's bodies provided by the slicing tool offers good results regarding the resulting product's dimensional stability but poor mechanical properties. Multiple extrusion systems allow for new opportunities regarding the manufacturing of multi-color and multi-material parts.

#Cura vs ultimaker cura update

When you're done, reopen the profile in Preferences > Profiles and click Update profile with current settings/overrides.Fused filament fabrication is an extrusion-based additive manufacturing technology with relatively low-cost equipment and a great variety of materials from standard to engineering grade. In the normal "Print settings" Cura panel, change the following settings: Print Settings I generally use a single profile and update quality from there, but that's up to you.Ĭlose the settings panel. Navigate to Preferences > Profiles > Normal, click Duplicate, and give it a name such as "Mega X Profile" or "Mega X Normal Profile".

#Cura vs ultimaker cura download

Download those profiles and import them in Preferences > Profiles. You can find importable Cura profiles for PLA and TPU on the USB drive that came with your printer, or mirrored on our GitHub repo. The default print settings inherited from the i3 Mega should work great for the Mega X, except that I recommend updating a few values (below). Now that the machine itself is configured, you can optionally change a few print profile settings for the Mega X. When you're finished, click Close to save. G28 X0 Y0 move X/Y to min endstops, so the head is out of the way G1 Z15.0 F move Z up a bit and retract filament even more Mega X Printhead Settings Printhead Settings Make sure the following Anycubic Mega X Cura settings are selected: Mega X Printer Settings Printer Settings

0 kommentar(er)

0 kommentar(er)